A truck roll is when a technician or service provider drives to a customer’s location to install or repair equipment. They are a necessary part of many customer and field service operations. And there will always be situations where a technician needs to be dispatched in-person to solve a problem with their special skills or equipment. However, a surprising number of visits end up being wasted on issues that could have been easily fixed by customers themselves had they have been given a little guidance. Reducing truck rolls wherever possible and when warranted is critical to improving efficiency and reducing carbon emissions.

Just like office workers get frustrated with hour-long “meetings that could have been a quick email”, customer service teams and consumers’ worst nightmare is a redundant visit that could have been solved autonomously and remotely. Companies always try to avoid in-person visits when possible because they are so expensive, given not only the time of the technician but also the cost of vehicles, fuel, and the time spent on the road. In many industries, driver wages and fuel costs alone make up 59.8% of the total operational cost per mile.

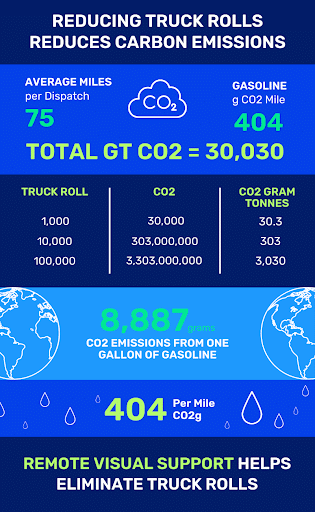

Beyond the huge financial burden that in-person visits carry, there is a very real environmental cost attached to them as well. Governments around the globe are trying to figure out ways to reduce the number of vehicles on the road, with initiatives that range from additional taxes to drive into the city center to incentives for ride-sharing work commutes.

What about the hundreds of thousands of field service vehicles constantly in circulation? What’s the best way to put a stop to wasteful, unnecessary visits? And what is the hidden environmental cost of redundant technician home visits?

There are three simple ways in which technology can help reduce truck rolls, which unnecessarily hurt the environment as well as companies’ bottom line.

- Improved Route Optimization

When your drivers have hundreds, if not thousands, of destinations or clients to visit, planning routes manually is a time-intensive and inefficient solution. So even small improvements to driver’s routes can reduce mileage, save a lot of time, and serve the clients that really need you much faster. With proper route optimization tools, businesses can save up to 20% in mileage and improve order capacity by as much as 100% without increasing their fleet.

With proper route optimization tools, businesses can save up to 20% in mileage and improve order capacity by as much as 100% without increasing their fleet.

Thanks to route optimization software, fleets can easily combine different transport flows, taking into account complex planning rules and restrictions. The software optimizes the routes, thereby increasing the load factor so that fewer vehicles are needed. In addition, high-quality route optimization software can integrate traffic data to minimize time lost, choosing routes based on historical traffic patterns. Less time spent in traffic jams means more efficient employees, happier customers, and a drastic reduction in unnecessary CO2 emissions.

- More Electric Vehicles

While electric vehicle sales jumped by 60% globally in 2022 to an all-time high, data from Counterpoint shows that they only accounted for just over 14% of the world’s passenger vehicle sales. When it comes to trucks, the room for improvement is even greater. Although today it’s a small market compared to passenger EVs, the electric truck market is projected to register a CAGR of 9.16%. Medium-duty trucks are projected to make up over 93% of the global electric truck fleet by 2026, with over 302,000 units in use worldwide.

A recent study by Scania carried out a Life Cycle Assessment, comparing the CO2 emissions of a battery electric distribution vehicle with a payload of 30 tons to a comparable distribution vehicle with a diesel engine. While the electric vehicle started out with a poorer emission balance when it left the production due to the battery manufacturing emissions, it quickly catches up as soon as the vehicle goes into operation. Given a projected service life of 500,000 kilometers, the study shows how battery electric vehicles can save more than 90 percent of carbon emissions.

- Ramp-up Virtual Assistance

The ultimate solution to reduce CO2 emissions is to drive less. Being better at screening customer issues or problems remotely is key. While there are instances in which a technician with specific skills will need to drive to a customer’s location to repair an issue, on many occasions a short call with visual assistance is all a customer needs.

Visual-led solutions which enable field technicians to inspect issues remotely are not only a better solution to cut overheads and carbon footprint. They are also preferred by customers, who would rather solve a situation autonomously with a little remote guidance.

This approach is paying huge dividends to companies such as ADT, a leading manufacturer of home security systems including cameras and alarms, recently reported that rolling out Virtual Assistance is transforming how our digital and physical worlds meet, allowing customers to more quickly troubleshoot system issues. Their newly launched program has successfully executed over 200,000 virtual service visits in the past three months, with approximately 80% truck roll avoidance success rate, generating high customer satisfaction scores at a lower cost to the company.

We can’t buy our way out…

Environmentally-friendly practices don’t have to come at the expense of productivity and efficiency. In fact, in the field service industry, they’re normally tied together since companies will always try to reduce unnecessary visits and wasted mileage.

Initiatives such as carbon credits are questionable. Earlier this month, a report showed that nearly 95% of the “avoided deforestation” carbon credits issued by Verra, the world’s largest certifier, have zero climate mitigation value. Thankfully, for us in the field services space, technological innovation such as EVs, Virtual Assistance, and Route Optimization software will help organizations modernize their operations and become more efficient – while drastically reducing their carbon footprint by reducing truck rolls.

So, where do we start? According to Vijay Sankaran, Johnson Controls VP and CTO, and his comment at Bloomberg’s recent Sustainability Summit, “Doing something is better than doing nothing.”