Contents

- Why Remote Maintenance is so Critical

- Remote Maintenance during COVID-19

- Shifting to Outcome-based Remote Maintenance Solutions

- Fixing the Problem before it Escalates with AR Remote Maintenance

- The Need for Remote Monitoring Tools

- Creating a Visual Remote Maintenance Strategy

- AR Remote Maintenance and Repair

Augmented reality remote maintenance and repair solutions are becoming increasingly popular among field service organizations.

These companies have long been implementing measures to reduce their high operational costs. Technician dispatches, in particular, are a huge drain on resources, considering that each truck roll involves technician labor costs and vehicle expenses such as fuel and insurance. Remote maintenance is therefore becoming a preferred solution for many field service organizations, as it enables technicians to monitor and maintain customer systems from afar using a range of tools and sensors.

Why Remote Maintenance is so Critical

Remote support technologies allow field service organizations to provide prompt, high-quality service and repair solutions, without needing to dispatch a technician to the customer’s site. The ability to maintain and repair equipment remotely is critical when it comes to minimizing downtime, whether it’s for example:

- an engineer overseeing a factory production line

- an IT technician upgrading a server, or

- an electricity company worker servicing a meter.

Remote Maintenance during COVID-19

The global coronavirus pandemic is further driving the need for remote maintenance and monitoring. Safety concerns and pared-down workforces mean that there is a smaller pool of technicians available to service customers. But the change is also being driven by customers. A new study examining consumer expectations of technical support and technician visits during the COVID-19 pandemic found the following results. While most still expect their providers to resolve service and equipment issues as quickly and effectively as before the pandemic, 75% do not want technicians in or around their homes unless strictly necessary.

Shifting to Outcome-based Remote Maintenance Solutions

The need to limit machine downtime, coupled with the changes caused by the current crisis, is resulting in a new operating model for many B2B field service organizations. Instead of following specific processes and protocols determined by SLAs and contracts, many companies are shifting to an outcome-based approach for their B2B customers. In this new model, the priority is keeping customer equipment up and running at all costs.

This simplifies contractual obligations for customers; instead of having to worry about the details of service plans, the field service provider just takes whatever steps necessary to avoid issues or resolve them as soon as possible, ensuring customer satisfaction.

Fixing the Problem before it Escalates with AR Remote Maintenance

For example, an oven manufacturer has a clear maintenance contract with its core customers: restaurants. In the event of a malfunction, a technician must be on site within 24 hours. However, every time the oven malfunctions, the restaurant’s operations are negatively affected for 24 hours until the technician arrives. If the oven breaks down twice in one month, the result is a negative customer experience, even if the manufacturer keeps to its SLA.

Instead, using an outcome-based model, the manufacturer may remotely monitor the oven’s gauges and sensors to ensure that it is in optimal working order. The manufacturer may even use remote computer maintenance technology to take proactive steps to prevent the malfunction occurring in the first place.

The Need for Remote Monitoring Tools

This requires a greater reliance on automated remote maintenance and assistance tools. Issues can be identified early. Additionally, when the fix is relatively simple, it can be performed by onsite staff guided by remote experts using augmented reality, rather than by engineers in the field.

Outcome-based service also means that technicians have to focus on a wider range of tasks to facilitate positive outcomes for customers, increasing the need for remote collaboration, guidance, and oversight. In fact, according to a Gartner survey from 2019, 19% of service companies already offered such contracts at the time, and another 26% expected to do so within 12 months.

Creating a Visual Remote Maintenance Strategy

As remote monitoring tools such as advanced sensors become more widely adopted, service organizations’ ability to implement a broader range of predictive maintenance solutions will increase. Measuring variables ranging from temperature and pressure to vibration and rotation speed, these systems can be deployed alongside the latest AI-powered approaches such as digital twins.

Adding a visual element to these remote maintenance technologies will take the effectiveness of field service organizations to the next level, in terms of both preventative and corrective procedures. With the right combination of technologies, enterprises can move toward a unified visual maintenance strategy.

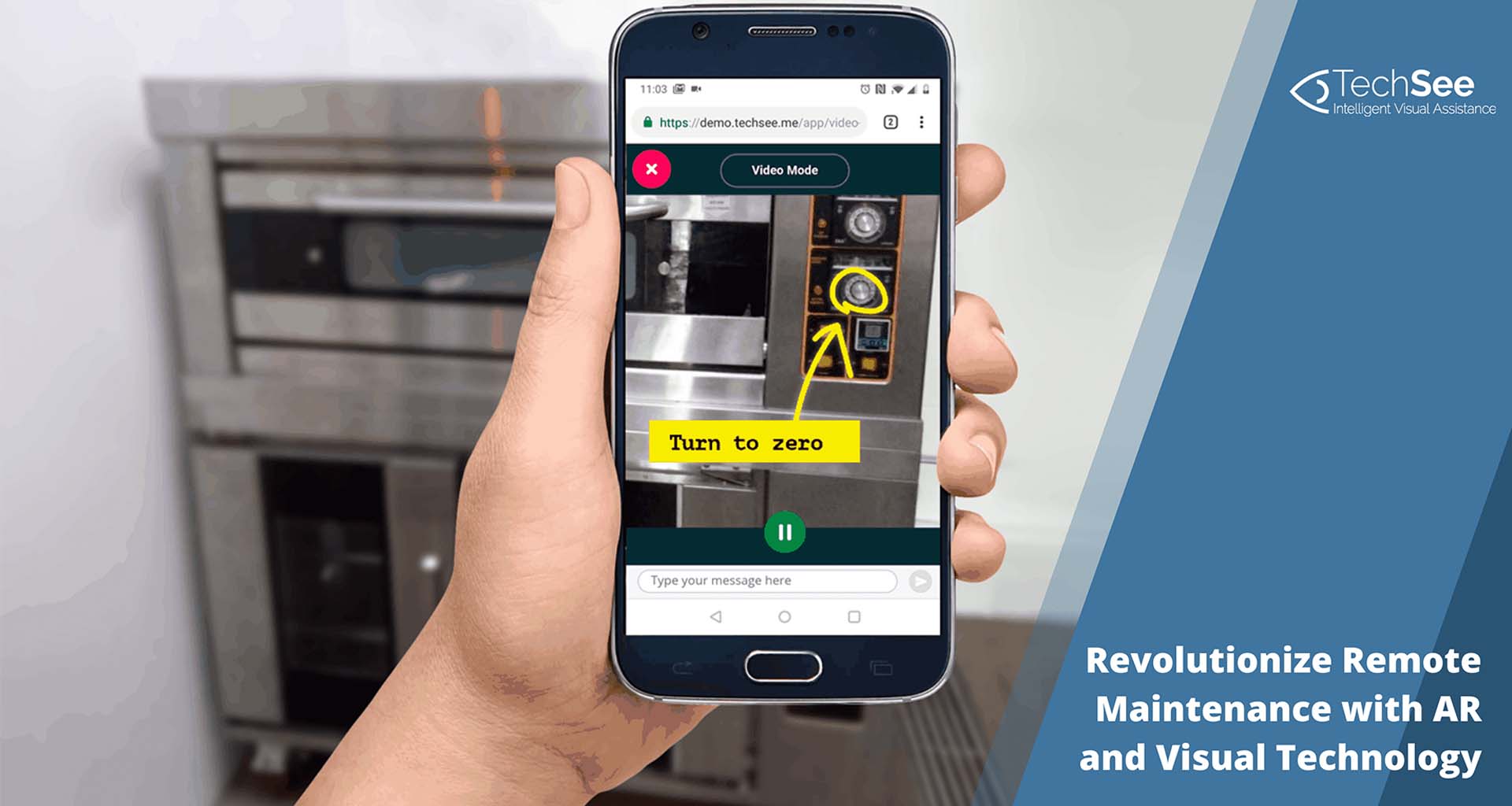

Visual assistance allows remote experts to see customers’ equipment via their smart device camera, and visually guide them to resolutions using on-screen augmented reality annotations. This enables fast, effective problem-solving, without the need for a time-consuming and costly dispatch.

For example, using visual assistance, a customer can show their equipment to the supplier who can ask to see specific areas of the machine in order to identify the problem. The remote expert can then guide the customer through a series of simple steps to fix it. They can use AR remote maintenance solutions to place instructions directly on what the customer sees in order to guide them in exactly what to do for the remote repair.

Computer Vision AI is the science of teaching machines to see, recognize and understand the physical world. The visual technology can identify devices, such as:

- A/C units

- dishwashers

- 3D printers

- medical technology, and

- industrial machinery.

It can recognize specific parts including wires, cables, pipes, fuses, and bearings. It can also spot faults such as fine cracks, component misalignments, and issues involving connected equipment and its status. This is in order to diagnose issues visually and suggest resolutions.

For example, a manufacturing facility is being monitored by a computer vision-based system. It detects that a red light is blinking on a specific machine, which triggers an alert to the foreman. Computer vision AI then provides the foreman with step-by-step AR guidance on how to resolve the problem, and the issue is fixed before the problem impacts production.

AR Remote Maintenance and Repair

Remote visual maintenance has already been proven successful in helping field service organizations improve operational efficiency and cut costs. The shift to outcome-based models for B2B customers is pushing suppliers to proactively support their equipment using remote computer maintenance technologies to drive higher rates of customer satisfaction.

Visual Assistance and Computer Vision AI can take remote maintenance to the next level by adding the visual layer on top of standard monitoring tools. Additionally, they offer full AR remote maintenance and repair solutions. Visual remote maintenance is therefore a game-changing technology that is ushering in a new age of field service capabilities, especially useful in the hands-off COVID-19 era.